The steel ball slide rail industry is experiencing technological innovation and market expansion, and domestic substitution is accelerating

Driven by the dual upgrading of global manufacturing intelligence and green development, the steel ball slide rail industry is undergoing technological iteration and market restructuring. As a core component in the field of precision transmission, steel ball slides are widely used in furniture, industrial equipment, new energy vehicles and other fields due to their high load-bearing capacity, smoothness and durability. Domestic enterprises are gradually breaking the monopoly of international brands and becoming an important force in the global industrial chain through technological breakthroughs and capacity optimization.

1. Technological breakthrough: Parallel development of domestic substitution and material innovation

(1) Domestic enterprises lead technological breakthroughs

As a leading domestic steel ball slide rail enterprise, Shanghai Chunyu Industrial Co., Ltd. has been rated as an excellent high-tech product for its interlocking heavy-duty three section steel ball slide rail, with a bearing capacity of 200kg and technical parameters benchmarking international brands, while reducing costs by 30% -50%. The company has introduced a fully automated production line to achieve millimeter level precision control of slide rail dimensions, and improved product corrosion resistance through material optimization (such as 304 stainless steel)

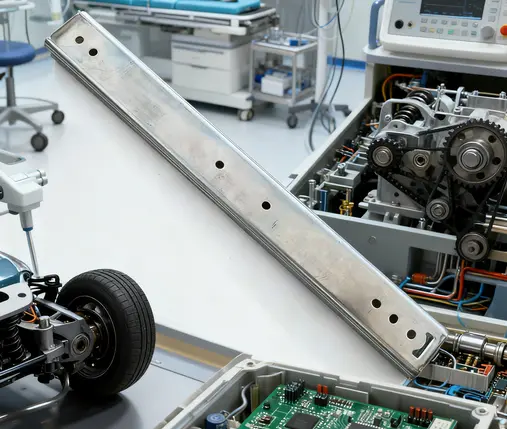

(2) New energy and industrial sectors: high loads and extreme environments pose challenges

The explosive growth of the new energy vehicle industry has opened up a new track for steel ball slide rails. In 2023, the market size of car slide rails will exceed 1.8 billion yuan, a year-on-year increase of 24%, mainly used in electric seat adjustment systems and battery pack module fixing devices. The BYD Han EV single model uses 22 sets of slide rails, which is 8 sets more than the same level of fuel vehicles, driving a surge in orders from domestic slide rail companies.

The industrial sector has a significant demand for high load sliding rails. In the application of 76mm heavy-duty steel ball slide rails in auto parts factories, the track deformation is only 0.08mm when carrying 200kg, and the monthly maintenance frequency has been reduced from 12 times to 2 times, resulting in a 50% increase in operation and maintenance efficiency. Shanghai Chunyu can customize high-temperature resistant sliding rails that can operate stably in a 200 ° C environment, becoming the preferred choice for chemical equipment.

Despite the broad prospects of the industry, steel ball slide rail enterprises still face multiple challenges: fluctuations in steel prices (with a 9% year-on-year increase in the average price of cold-rolled steel in Q1 2024) and increased pressure for technological upgrades due to EU REACH regulations; In terms of international trade, the adjustment of tariffs between China and the United States can alleviate export pressure in the short term, but in the long run, it is still necessary to consolidate market position through technological differentiation.

In the future, the industry will present three major trends: firstly, accelerated material innovation, with an increase in the proportion of aluminum alloys, carbon fibers, and bio based materials; The second is the deep integration of intelligence and IoT technology, and the slide rail integrated with sensors can achieve real-time status monitoring; Thirdly, the application scenarios will be further subdivided, with liquid cooled servers, intelligent warehousing, and new energy equipment becoming the main drivers of growth. As the advantages of domestic enterprises in technology, cost, and service gradually emerge, the steel ball slide rail industry is expected to occupy a more important position in the global industrial chain.