0102030405

Selection Guide for Heavy-Duty Stainless Steel Drawer Slides

2025-11-26

I. Load-Bearing Performance: Core of Safety in Heavy-Load Scenarios

The selection of heavy-duty stainless steel drawer slides should match the load weight, usage frequency, and stress mode, achieving a balance between "precise adaptation and safety margin" to avoid deformation due to insufficient load-bearing capacity or cost waste from over-selection.

Core Parameters: Dual Considerations of Static and Dynamic Load-Bearing

Load-bearing capacity is divided into "static load-bearing" (load capacity for static storage) and "dynamic load-bearing" (load capacity for pushing and pulling operations). Both are crucial in scenarios with frequent access. The general rule is that static load-bearing should be ≥ 1.2 times the actual load to reserve a safety margin.

Typical Load Matching Solutions:

-

Light-load and low-frequency scenarios (e.g., regular equipment storage in medical carts): Load ≤ 50kg, select Type 51 slides with a static load-bearing capacity of 75kg;

-

Medium-load and high-frequency scenarios (e.g., tool cabinets in coastal factories): Load 50-80kg, 304 stainless steel slides with corrosion resistance and detachable inner rails offer excellent adaptability and maintainability;

-

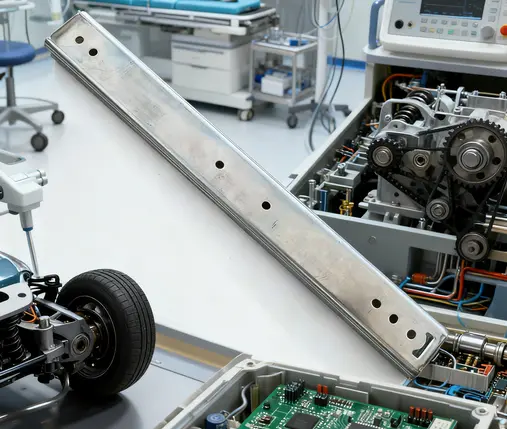

Heavy-load and extreme scenarios (e.g., generator compartments, heavy-duty shelves): Load 150-230kg, 304 stainless steel slides combined with a triple full-extension structure (static load-bearing capacity of 220kg) are suitable for harsh heavy-load environments.

(Special Note: When a product only marks "maximum load-bearing", it is necessary to confirm that it refers to the static value; if the drawer depth exceeds 600mm or there is eccentric load (e.g., large hydraulic tools), the load-bearing capacity should be increased by an additional 20%, and thickened materials or three-row ball structures should be preferred.)

Material and Structure: Dual Guarantee for Load-Bearing Performance

Stainless steel material and structural design jointly determine the maximum load-bearing capacity, and different models vary significantly in applicable scenarios:

-

304 Stainless Steel: Optimal versatility, containing 8%-10% nickel, with a static load-bearing capacity of 25-220kg. It is suitable for general corrosive scenarios such as humid workshops and food processing. Representative Truslide models include the SS2053PT (load-bearing 120kg) and SS2076PT (load-bearing 227kg);

-

316L Stainless Steel: Enhanced corrosion resistance, containing 2%-3% molybdenum, resistant to chemical reagents such as alcohol, with a static load-bearing capacity of 30-100kg. It is specially designed for medical equipment cabinets and laboratory equipment;

-

High-Strength Stainless Steel Alloy: Containing manganese, chromium, etc., with a static load-bearing capacity of 80-230kg. Combined with thickened rails, it is suitable for ultra-heavy-load scenarios such as robotic arm storage in automotive welding workshops.

Structural Optimization Suggestions: Three-row ball design to distribute load; rail thickness ≥ 1.5mm to enhance deformation resistance; side ribs to extend service life by more than 50%.

Click to view the detailed product images of Truslider SS2053PT, and unlock the core parameters and application scenarios

Click to view the detailed product images of Truslider SS2076PT, and unlock the core parameters and application scenarios

II. Installation Adaptability: Key Factor Affecting Efficiency and Maintenance

Installation and maintenance in industrial scenarios involve professional labor. The structural design of drawer slides directly affects efficiency and costs. The core selection points are detachable structure, positioning assistance design, and scenario compatibility.

Detachable Structure: Core of Efficiency

Traditional slides require precise alignment during installation and complete emptying of drawers for disassembly during maintenance. Detachable inner rails support the process of "fixing the outer rail first, then installing the inner rail", and the snap-on connection increases installation efficiency by more than 40%. In an automotive welding workshop application, the installation time was reduced from 8 hours to 4 hours.

During maintenance, the inner rail can be disassembled without emptying the drawer, reducing downtime. This is particularly applicable to high-frequency scenarios such as medical care and manufacturing. After application in the CT room of a top-tier three hospital, the maintenance cycle was extended to 2 years, and downtime costs were reduced by 70%.

Positioning and Compatibility: Guarantee of Precision

Positioning assistance design ensures installation precision: positioning holes prevent deviation, scale marks ensure consistent height, and anti-deviation clamps prevent loosening. After application in an e-commerce warehouse, the shelf jamming rate decreased from 15% to 2%.

For compatibility, it is necessary to confirm that the "side panel thickness adaptation range" and "installation hole spacing" match the cabinet body; the smooth surface of stainless steel requires anti-slip components with gaskets for fixation; modular design can adapt to multiple cabinet structures and reduce customization costs.

III. Scenario Adaptability: The Art of Balancing Durability and Environment

The durability and adaptability of heavy-duty stainless steel drawer slides depend on surface treatment and functional configuration. Precise selection based on the environment is required to conform to the trend of intelligence and environmental protection.

Surface Treatment and Functional Configuration

Surface treatment should match the corrosive environment: polishing treatment is used for general humid scenarios; zinc-nickel alloy coating (meeting 48-hour salt spray test standards) is selected for coastal high-salt-spray scenarios; mirror polishing is used for medical and food scenarios to balance cleanliness and bacteria resistance.

Functional configuration is optimized for specific needs: buffer dampers and rubber strips are equipped for quiet scenarios (noise ≤ 30 decibels); two-way self-locking devices are used for mobile scenarios (locking in 0.2 seconds, resistant to 0.5g acceleration); special grease is applied for low-temperature scenarios (smooth operation at -30℃).

Typical Scenario Analysis

-

Manufacturing and Warehousing: For heavy loads, select Truslide SS2076PT (76mm wide rail + triple full-extension, excellent anti-torsion performance);

-

Medical and Clean Scenarios: 316L stainless steel models are suitable for equipment cabinets, resistant to alcohol disinfection, with a pushing-pulling precision of 0.05mm after 150,000 cycles;

-

Mobile and Outdoor Scenarios: Ultra-thin models are suitable for RVs and vehicle-mounted equipment, meeting heavy-load requirements and passing military standard tests.

Brand and After-Sales Service: Ensuring Long-Term Reliability

Priority should be given to established brands (such as Truslider) that provide comprehensive after-sales support. Reputable manufacturers offer installation guidance and maintenance services for all material types to ensure timely problem resolution. This aligns with the growing demand for reliable industrial equipment driven by global manufacturing upgrading.