News Categories

Featured News

0102030405

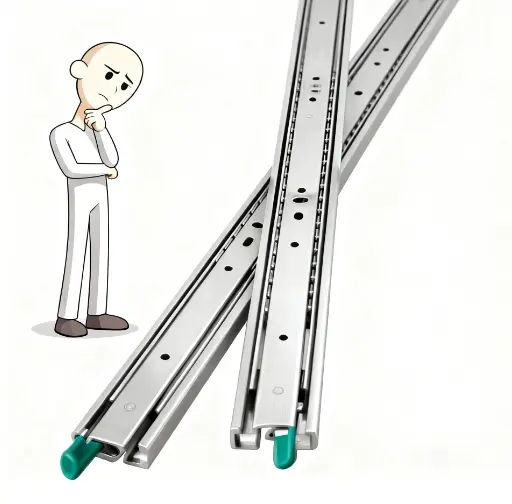

How to Select Slide Rails for Heavy-duty Tool Cabinets? Key Guide for Load Capacity & Installation

2025-10-31

I. Load Capacity: The Non-negotiable Safety Baseline

Selecting slide rails for heavy-duty tool cabinets does not follow a "higher load capacity = better" logic. Instead, it requires matching the total tool weight, usage frequency, and force application patterns to choose products with "compatible capacity plus adequate safety margin." This avoids rail deformation or jamming from insufficient load-bearing, as well as unnecessary cost waste from over-specifying high-capacity options.

Core Parameters: Static vs. Dynamic Bearing

Slide rail load capacity is categorized into "static bearing" (maximum weight supported when stationary) and "dynamic bearing" (maximum weight supported during pushing/pulling). Given that heavy-duty tool cabinets typically store tools long-term and endure frequent drawer operation, both parameters are critical. A general rule: select slide rails with a static bearing capacity ≥ 1.2 times the total tool weight to reserve safety margin.

- For tool cabinets with total tool weight ~35kg: Choose slides with 45kg static bearing (e.g., Truslider CS1345PT).

- For tool weight 50–80kg: Opt for 60–100kg static bearing models (e.g., Truslider CS1653PT).

- For tool weight <20kg with lightweight requirements: Select 25–30kg static bearing slides (e.g., Truslider CS1620PT).

Note: If a product only labels "maximum bearing capacity," confirm it refers to static bearing. For cabinets with drawer depth exceeding 600mm or eccentric heavy tools (e.g., large wrenches, hydraulic equipment), increase load capacity by 20% to avoid local stress damage—bearing steel or thickened carbon steel slides are ideal for such scenarios.

Material & Structure: Hidden Drivers of Load Capacity

Load capacity is not solely determined by parameters; material and structural design provide fundamental support. Different materials offer distinct load limits and scenario adaptability:

- Carbon steel/cold-rolled steel (SPCC): High mechanical strength and deformation resistance, with 30–80kg static bearing. Suitable for most medium-to-heavy-duty tool cabinet applications.

- Bearing steel: High carbon content for excellent hardness and wear resistance, supporting 80–150kg static bearing. Ideal for storing ultra-heavy tools like large hydraulic equipment and metal molds.

- Stainless steel: Superior rust and corrosion resistance, with 25–60kg static bearing. Perfect for humid, oily, or high-cleanliness environments (e.g., food processing workshops, outdoor maintenance stations).

- Aluminum alloy: Lightweight (1/3 the density of carbon steel) with 15–40kg static bearing. Suitable for weight-restricted scenarios (e.g., mobile tool cabinets) and lighter tools.

Structural design recommendations (material-independent):

- Multi-ball design (e.g., 3 rows of balls) distributes weight evenly and reduces single-point stress.

- Track thickness: ≥1.2mm for carbon steel/bearing steel; ≥1.5mm for aluminum alloy/stainless steel.

- Side reinforcing ribs enhance deformation resistance and extend service life.

II. Installation Convenience: A Direct Driver of Efficiency & Maintenance Costs

Installing and maintaining heavy-duty tool cabinet slide rails often requires professional labor. Complex designs increase installation time and labor costs, while improper installation can compromise performance. Key selection criteria include detachable structures, positioning aids, and compatibility—features that can be optimized via structural design across all materials.

Detachable Inner Rail: Simplify Installation & Maintenance

Traditional slide rails require precise alignment between drawers and tracks, with full drawer disassembly needed for maintenance. Detachable inner rail designs allow fixing the outer rail to the cabinet first, then installing the inner rail on the drawer separately, enabling quick assembly via snap fasteners. This eliminates repeated alignment adjustments and boosts installation efficiency by over 40%.

For later maintenance or rail replacement, only the inner rail needs removal—no need to empty the drawer’s tools—reducing downtime. This is particularly valuable for high-frequency workshop use, regardless of whether lightweight aluminum alloy or heavy-duty bearing steel slides are selected.

Positioning Aids: Reduce Errors & Enhance Stability

Installation precision directly impacts slide rail smoothness, and positioning aids (material-independent) are critical:

- Positioning holes enable quick track fixation to avoid left-right deviation.

- Scale markings ensure uniform installation height for multiple drawers, guaranteeing balanced force during operation.

- Anti-offset clamps secure tracks post-installation to prevent loosening over time.

These designs are available across carbon steel, stainless steel, and aluminum alloy slides, serving as a universal upgrade for installation convenience.

Compatibility & Adaptability: Avoid Size Mismatches

Drawer widths and depths vary across tool cabinet brands and models. When selecting slides, confirm their compatible size range and consider material-specific installation details:

- Aluminum slides: Softer material; avoid excessive force during installation and use matching special screws to prevent deformation.

- Stainless steel slides: Smooth surface; use anti-slip fixed pieces with pads for secure installation.

- Carbon steel/bearing steel slides: Heavyweight; ensure cabinet side panels have sufficient load-bearing capacity to avoid deformation.

Key compatibility checks: Verify that the slide rail’s "drawer side plate thickness range" and "installation hole spacing" match the tool cabinet. Prioritize highly versatile models or provide cabinet dimensions to manufacturers for custom solutions (all materials support customization).

III. Additional Considerations: Balancing Durability & Scenario Adaptability

Beyond load capacity and installation convenience, durability and scenario adaptability are primarily determined by material selection, aligned with industry trends toward smart, eco-friendly manufacturing.

Surface Treatment: Material-Specific Optimization

- Carbon steel/bearing steel: Electro-galvanizing or powder coating to enhance rust resistance.

- Stainless steel: Polishing or mirror finishing for improved corrosion resistance and aesthetics.

- Aluminum alloy: Anodization to boost hardness and wear resistance.

Silent Design: Material-Independent Comfort

Silence can be achieved across all materials via silent rubber strips and buffer damping. Ideal for noise-sensitive environments like office-adjacent workshops or laboratory tool cabinets.

Brand & After-Sales: Ensure Long-Term Reliability

Prioritize established brands (e.g., Truslider) with comprehensive after-sales support. Reputable manufacturers provide installation guidance and maintenance services for all material types, ensuring timely resolution of issues. This aligns with the growing demand for reliable industrial equipment amid global manufacturing upgrades.

Industry Best Practices to Consider

- Smart integration: Some high-end slides now support compatibility with RFID sensors, enabling tool tracking and inventory management synced with MES/ERP systems.

- Eco-friendly materials: Manufacturers are adopting recyclable metals to meet ESG requirements, a key consideration for global enterprises.

- Customization: Tailored solutions for specific industries (e.g., automotive, aerospace) are on the rise, with slides optimized for unique workflow and space needs.

Would you like to further adjust the depth of technical details, add more case studies, or optimize keyword distribution to enhance SEO performance?