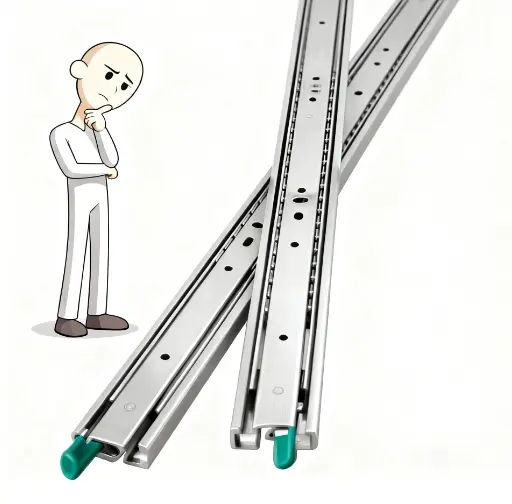

CS1620PT Slide Rail: An Innovative Product for Efficient Space Solutions in Multiple Scenarios

Recently, a sliding rail named CS1620PT has attracted significant attention in the market due to its outstanding performance and wide range of application scenarios. This sliding rail, with its compact design, strong load-bearing capacity, and environmentally friendly material processing techniques, has become the preferred sliding solution for many equipment manufacturers.

One of the major advantages of the CS1620PT sliding rail is its ease of installation. Due to its compact size and full telescopic pull-out design, it can flexibly adapt to the internal structure of equipment with limited space, without requiring a large amount of additional installation space. This is particularly important for compact industrial control units, thin and light office equipment, etc., where space is at a premium. The full telescopic pull-out function enables installers to easily reach all connection points of the sliding rail, significantly simplifying the operation process, reducing the time and manpower required for installation tasks, and improving overall work efficiency.

In terms of load-bearing capacity, the CS1620PT sliding rail performs exceptionally well, with a maximum load capacity of 25 kilograms. This enables it to securely fix heavy components such as paper tray assemblies inside printers and module supports in industrial control cabinets, even when subjected to constant weight for a long time, while maintaining excellent operational stability and effectively avoiding problems such as rail deformation or equipment failure due to insufficient load-bearing capacity.

In terms of materials and surface treatment, the main components of the CS1620PT sliding rail are made of cold-rolled steel (SPCC), which provides a solid structural foundation for the rail with its high strength and excellent toughness, enhancing the rail's impact resistance and wear resistance. Additionally, the surface of the rail is treated with an environmentally friendly electro-galvanizing process, which not only significantly extends the lifespan of the rail but also meets the high standards of modern enterprises for green production.

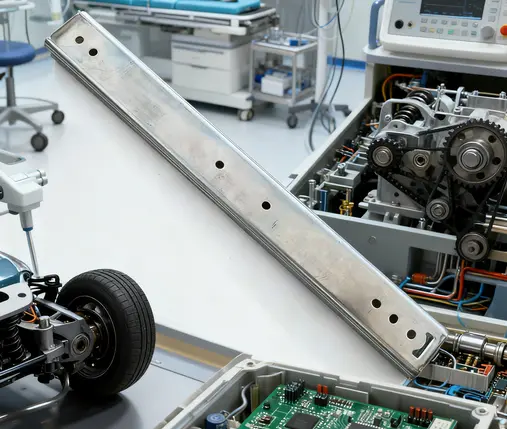

The application scenarios of the CS1620PT sliding rail are very extensive. In the office equipment field, it can be used in drawer-type filing cabinets, multifunction printers, etc., ensuring the smooth movement of components; in industrial electronic equipment, it can perfectly fit the internal sliding structure of various control cabinets and operation platforms; in display stands, it supports the layer sliding of display stands, facilitating staff access or organization of goods. Moreover, its stable performance and reliable material quality make it suitable for medical equipment, automotive parts, and other fields, meeting the diverse needs of different equipment.

As the demand for efficient space solutions in the market continues to increase, the CS1620PT sliding rail, with its outstanding performance and wide applicability, is expected to gain wider application and market recognition in the future.