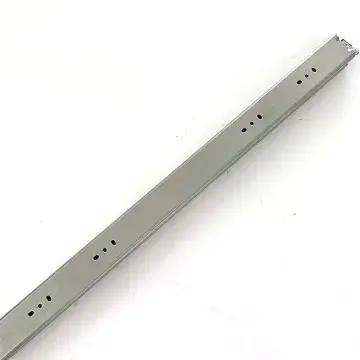

CS1620PT Slide Rail: An Efficient Space Solution Suitable for Multi-Scenario Equipment

description1

Product Introduction

The CS1620PT slide rail stands out with remarkable advantages in the installation process, thanks to its compact size and full-extension pull-out design. Its small footprint enables flexible adaptation to the internal structure of equipment with limited space, eliminating the need to reserve a large amount of extra installation area—this is particularly crucial for devices where every inch of internal space is valuable, such as compact industrial control units or slim office machines.

Meanwhile, the full-extension pull-out function allows installers to easily reach all connection points of the slide rail without awkward maneuvering. Whether it is the initial assembly of new equipment, regular maintenance checks, or disassembly for part replacement, this design significantly streamlines the operation process, reduces the time and labor required for installation-related tasks, and ultimately boosts overall work efficiency.

In terms of load-bearing performance, the CS1620PT slide rail boasts a maximum load capacity of 25 kilograms. This robust load-bearing capability ensures stable support for various components in office equipment and industrial electronic devices. For instance, it can securely hold the paper tray assembly inside printers (which often carry multiple reams of paper) and the module brackets in industrial control cabinets (that house heavy electronic components). Even when bearing a constant weight over long periods, the slide rail maintains exceptional operational stability, effectively preventing issues like slide rail deformation or equipment malfunctions that may arise from insufficient load-bearing capacity.

When it comes to materials and surface treatment, the main components of the CS1620PT slide rail are crafted from cold-rolled steel plate (SPCC). This material is renowned for its high strength and excellent toughness, providing a solid structural foundation for the slide rail. It enhances the rail’s resistance to impact (such as accidental bumps during equipment handling) and wear (caused by repeated pushing and pulling over time), ensuring long-term structural integrity.

The surface of the slide rail is treated with an environmentally friendly electro-galvanizing process. significantly extending the slide rail’s service life. Moreover, the electro-galvanizing process adheres to strict environmental standards, avoiding environmental pollution during both production and usage phases. This aligns perfectly with the green production demands of modern enterprises, which prioritize sustainability alongside product performance.

Another key highlight of the CS1620PT slide rail is its wide range of application scenarios. In the field of office equipment, it is widely used in drawer-type file cabinets (enabling smooth opening and closing of file drawers) and multi-functional printers (facilitating the easy pull-out and push-back of paper trays or maintenance compartments), ensuring seamless movement of components.

In industrial electronic equipment, it fits perfectly into the internal sliding structures of various control cabinets and operation platforms, allowing technicians to access internal modules quickly during debugging or repairs. For display shelves, it supports layered sliding of display racks, making it easier for staff to retrieve or arrange goods—ideal for retail stores or warehouse display areas.

Additionally, its stable performance and reliable material quality make it suitable for medical equipment (such as the drawer components of medical carts, which need to operate smoothly even when holding medical supplies) and automotive parts (like the slide rails for car storage boxes, which must withstand frequent use in a vehicle’s dynamic environment). Across all these fields, the CS1620PT slide rail consistently delivers high-quality sliding solutions, meeting the diverse needs of different devices.