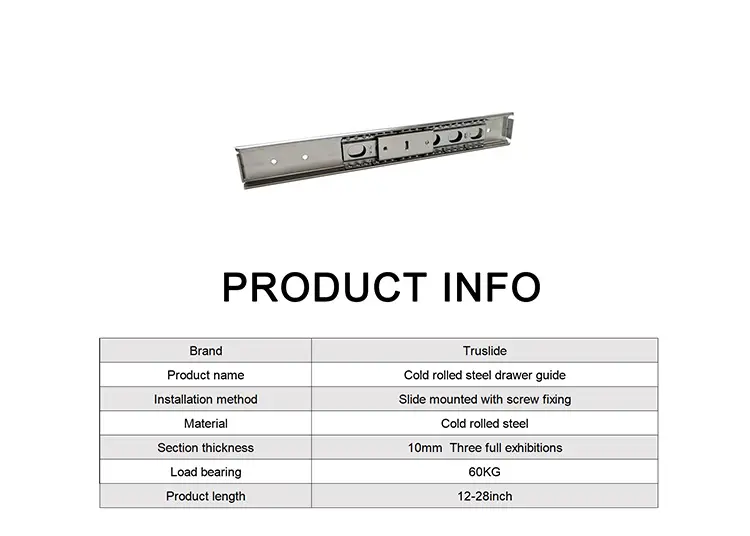

CS1035nhk, a steel mid-load slide rail, has low vibration, smooth and stable operation, and can handle a load of 60kg

description1

Product Introduction

In the fields of industrial production and public facilities, the CS1035NHK slide rail demonstrates extensive scene adaptability with its outstanding performance. For the machine manufacturing scenario, its cold-rolled steel material's wear resistance and 60kg load capacity can meet the guiding requirements of mechanical components during long-term reciprocating motion, reducing wear and loss. In the public vehicle sector, the stable support characteristics of the slide rail can ensure the safe fixation and flexible adjustment of interior equipment components. In scenarios such as diagnostic equipment, which have extremely high precision requirements, the precise guiding function of the CS1035NHK slide rail can assist in achieving precise position control of components, facilitating the accurate execution of diagnostic work, and covering the diverse usage needs across various domains.

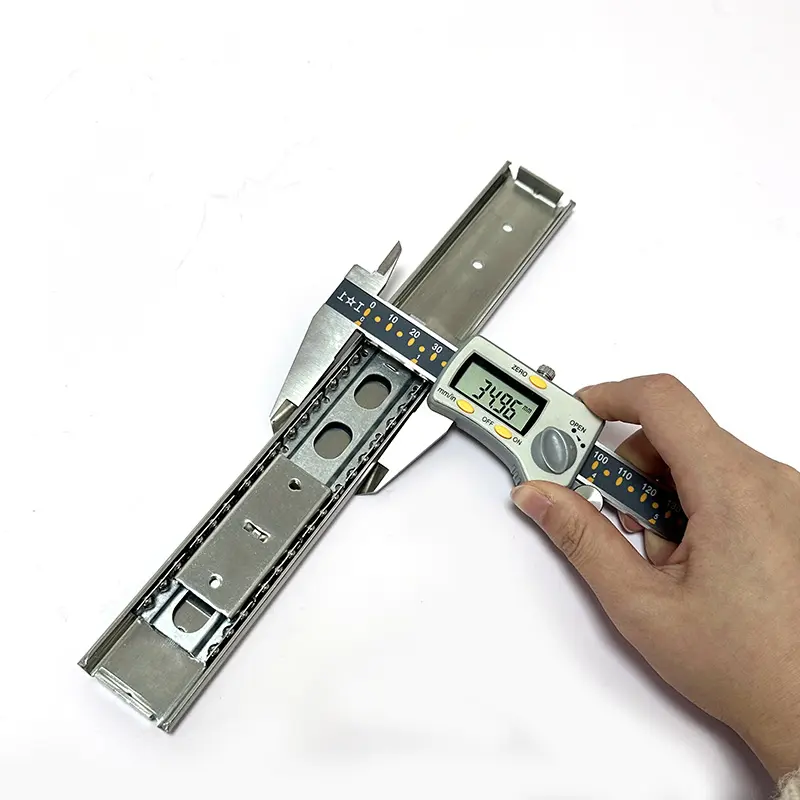

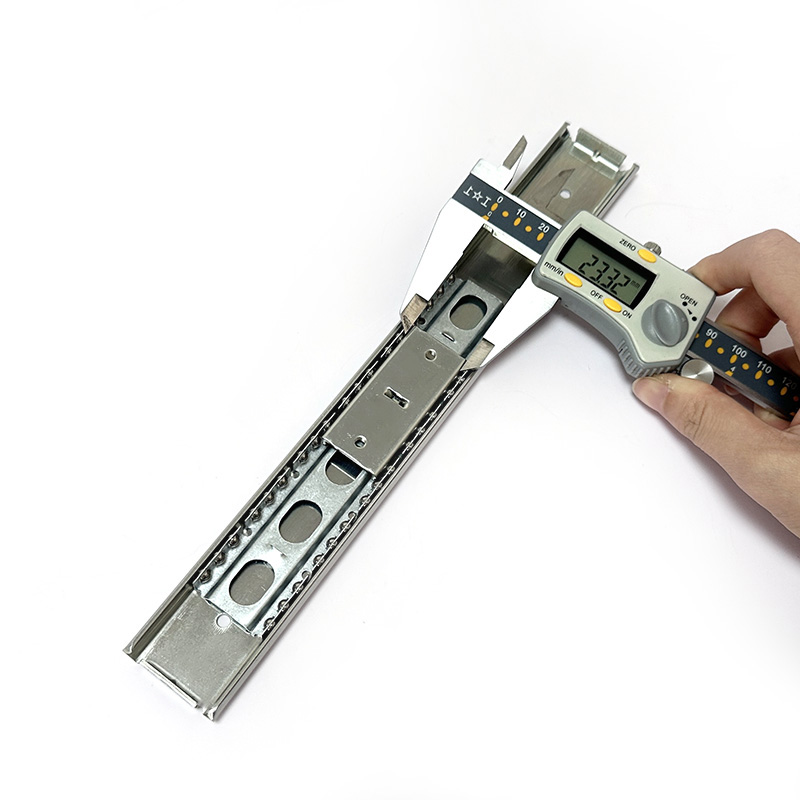

Detail

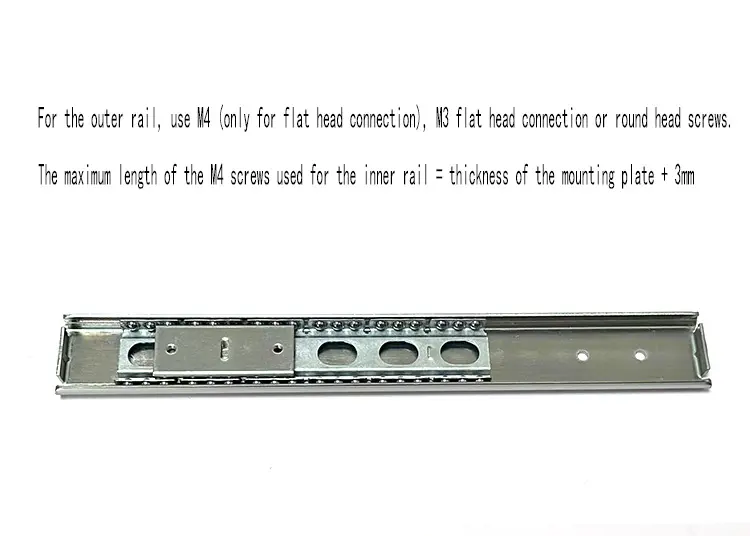

The CS1035NHK slide rail, based on standardized production, has further introduced flexible customization services, with the core focus on users' custom requirements for hole positions. Due to the differences in installation structures and fixation methods of various devices, standardized hole positions often cannot be fully adapted. The customized hole position service can precisely process the corresponding hole positions based on the equipment installation drawings or specific parameters provided by users, ensuring a perfect connection between the slide rail and the equipment, eliminating the trouble of users' subsequent secondary processing. At the same time, the product not only supports customized hole positions made of cold-rolled steel, but also allows stainless steel 304 material models of the same size and function to be customized simultaneously. This fully takes into account users' dual personalized requirements for material and installation details, improving the equipment assembly efficiency.

Advantage

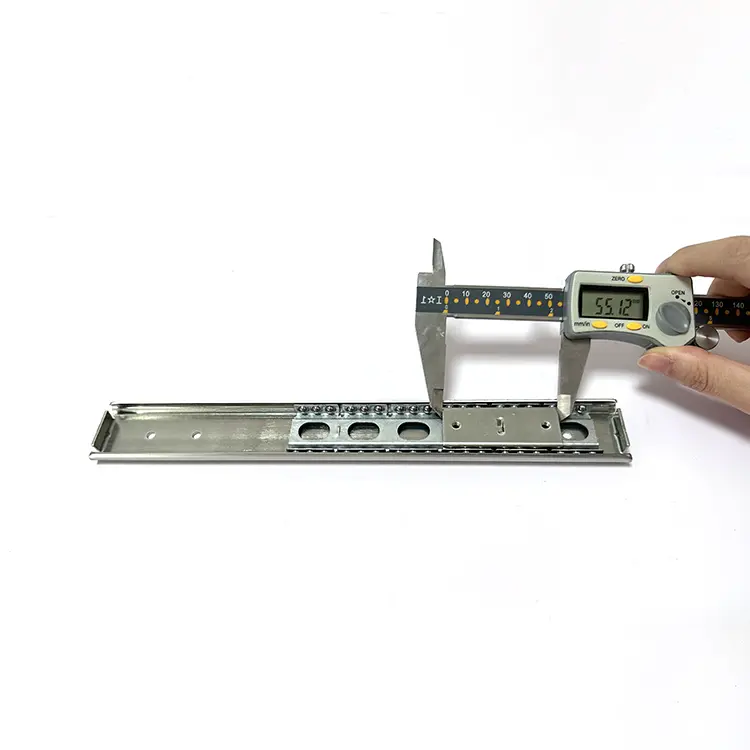

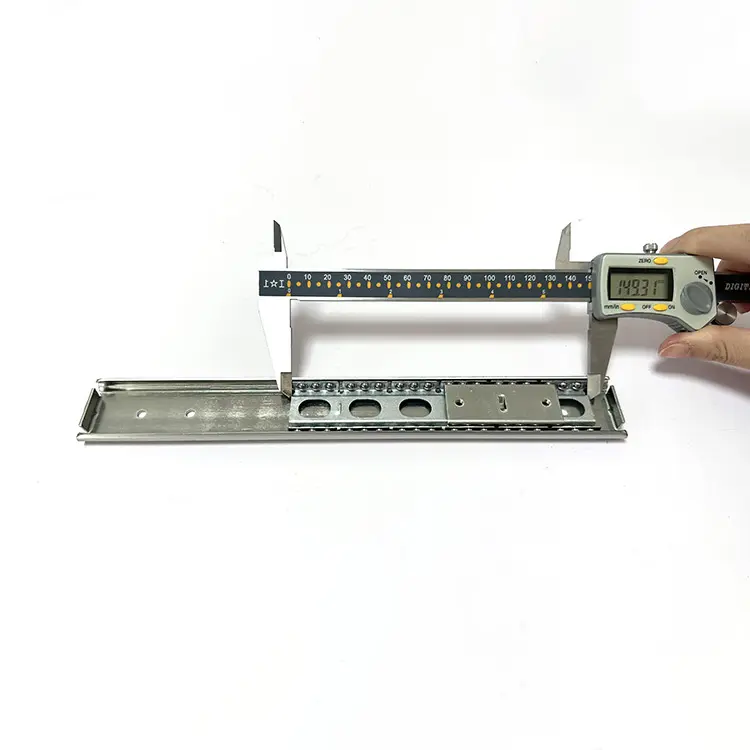

CS1035NHK internal sliding block type slide rail, made of high-quality cold-rolled steel as the base material, with a thickness of 10mm and a width of 35mm, forms a stable and reliable structural framework, making it an ideal choice for medium-load scenarios. Its size covers the mainstream range from 12 inches to 28 inches, can meet the installation needs of most devices, and also supports customization of the same specification. As a steel medium-load type slide rail, the product can support a maximum load of 60kg, performing exceptionally well in terms of load-bearing performance. Whether it is guiding the internal components of the machine, supporting the equipment structure, or adjusting the position of precision components, it can provide stable operation guarantees and lay a solid foundation for the efficient operation of the equipment.

Application

The CS1035NHK slide rail offers users two high-quality material options to meet the usage requirements in different scenarios. The cold-rolled steel model, with its mature cold-rolling process, has excellent strength and toughness. With a maximum load capacity of 60kg, it can handle most medium-load scenarios and has a more favorable cost advantage, making it suitable for industrial machines, public vehicles, and other scenarios where the corrosion resistance of the material is relatively lower. The stainless steel 304 model significantly improves corrosion resistance and can resist the erosion of humid, acidic, and alkaline environments. It is more suitable for diagnostic equipment, medical instruments, or outdoor public equipment, which have higher requirements for material weather resistance and hygiene. Both models maintain a thickness of 10mm, a width of 35mm, and a size range of 12-28 inches. This ensures that the basic performance and installation compatibility of the slide rail are not affected regardless of the material choice.