AL2027pt is small in size, occupies little space, can carry a load of 25kg, and is made of aluminum alloy.

description1

Product Introduction

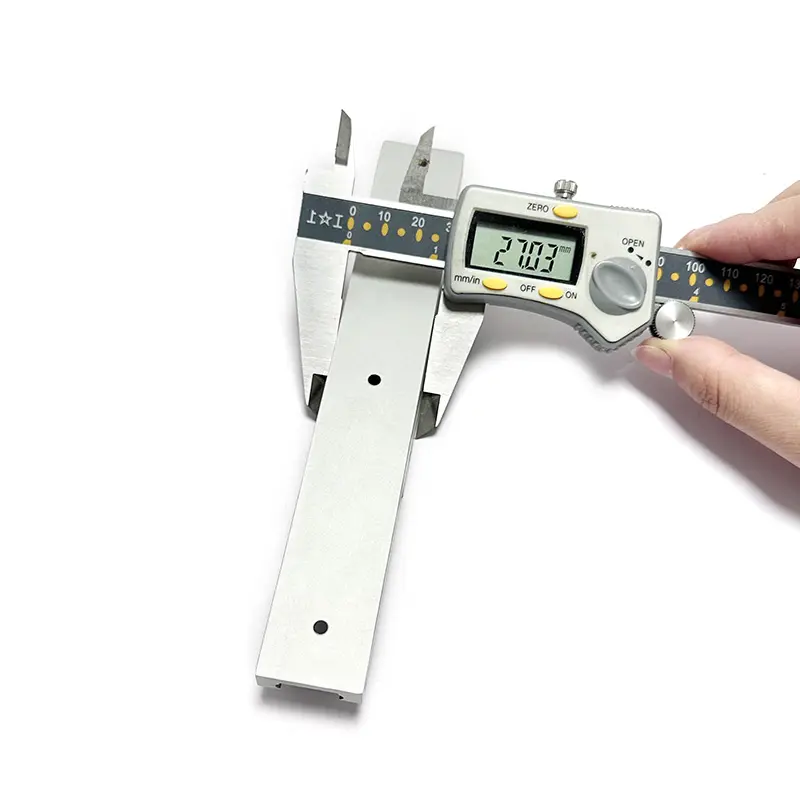

AL2027pt, as a representative product of the aluminum alloy series of light-load slide rails, has become the ideal choice for light-load scenarios due to its compact design and reliable performance. Its core parameters are highly competitive: a width of only 27mm and a thickness of 20mm. The extreme size control enables it to easily fit into the structures of equipment with limited space, effectively reducing the valuable space occupied by installation. It is particularly suitable for precision equipment with strict requirements for compact layout. The product is made of high-quality aluminum alloy, achieving lightweight while possessing excellent corrosion resistance and wear resistance, extending the service life. The rated load capacity can reach 25kg, fully meeting the light-load sliding needs of measuring instruments, industrial electronic equipment, and various precision instruments. Whether it is component pushing and pulling, drawer-type structures, or precise adjustment mechanisms, it can provide a smooth and quiet running experience, ensuring the accuracy and stability of equipment operation.

Detail

The AL2027pt aluminum alloy light-load slide rail, with its "small size, low load, and high precision" characteristics, demonstrates excellent adaptability in multiple professional fields. In the field of measuring instruments, such as optical measuring instruments and coordinate measuring machines, its compact size of 27mm×20mm can be perfectly integrated into the sliding mechanism of the detection platform inside the instrument. With a load capacity of 25kg, it is sufficient to support the smooth movement of the detection module, avoiding the impact on the measurement accuracy of the instrument due to the excessive size of the slide rail. In industrial electronic equipment, it is often used in the pull-out modules of server cabinets and the sliding structures of operation panels of industrial control boxes. The small size design allows for more orderly wiring inside the equipment, and the lightweight advantage of aluminum material also reduces the overall weight of the equipment. In the category of precision instruments, such as biological experimental instruments and semiconductor detection equipment, the smooth sliding characteristic of AL2027pt can reduce vibration interference during the operation of the mechanism, ensuring the accuracy of experimental data and detection results, and becoming a key component of the transmission system of precision equipment.

Advantage

Compared with traditional steel slide rails or large aluminum alloy slide rails, AL2027pt has significant advantages in light-load application scenarios. Firstly, the space utilization rate has been greatly improved - the width of traditional light-load slide rails is usually over 30mm, while AL2027pt is only 27mm wide and 20mm thick. For small measuring instruments and compact industrial electronic equipment, it can save 10%-15% of installation space, leaving more layout space for other core components inside the equipment. Secondly, it is lighter in weight. Compared with the same specification steel slide rails, the weight of aluminum alloy is reduced by about 40%, effectively reducing the overall load of the equipment. It is especially suitable for portable measuring instruments that are sensitive to weight. Moreover, it has a higher cost performance. Under the premise of meeting the 25kg light-load requirement, there is no need to choose large-load redundant slide rails. It can not only control the procurement cost but also avoid the redundancy of equipment structure caused by "using too much material for too little work", achieving a balance between performance and cost.

Application

When purchasing AL2027pt aluminum alloy light-duty slide rails, it is necessary to focus on three key points based on the actual application scenario: First, load matching. Confirm that the weight of the sliding components of the equipment does not exceed the rated load of 25kg to avoid deformation or jamming of the slide rails due to overloading; Second, installation dimensions. Check whether the 27mm width and 20mm thickness are compatible with the reserved space of the equipment, and clearly define the length requirement of the slide rails to ensure that the sliding travel meets the operation requirements of the equipment; Third, environmental adaptability. If it is applied in a humid or slightly corrosive industrial environment, you can request the manufacturer to provide an enhanced version with surface oxidation treatment to further improve the anti-corrosion performance. During installation, pay attention to: Maintain the parallelism of the slide rails and the installation surface to avoid poor sliding due to installation tilt; Use matching small screws for fixation to ensure uniform spacing of the fixation points and enhance installation stability; After installation, conduct load-free and load tests to check if the sliding is smooth and there is no abnormal noise, ensuring compliance with the operation requirements of the equipment.